Chemical Engineering Capstone Projects Give Students Hands-On Experience

Chemical engineering students at McNeese State University finished out their year with senior capstone projects that had them working hands-on with local industry and faculty mentors.

For their projects, students were tasked with fixing existing issues or providing plans for making present processes more efficient in a variety of areas related to chemical engineering. Among these projects, students designed and selected recycle compressors for a distillate upgrade project for Phillips 66, made plans for upgrading primary compressor intercoolers for Westlake Chemical, designed a process for minimizing solids carryover of the alcohol hydrolysis process for Sasol and outlined processes for algae-based biofuel production.

Projects were overseen by industry and faculty mentors, who helped guide and assist students by providing technical information and advice. Before the stay-at-home order was issued due to coronavirus, students had the opportunity to tour facilities and see the potential impacts of their research and development firsthand.

Patrick Green, whose team worked with Citgo on the project “Alkylation Feed Header Debottleneck,” says, “Citgo was very accommodating at the first half of the semester and we were able to go out to the field numerous times. If we had issues locating items, we had to go into the control room and work with the operators and receive their help. From an operational standpoint, it was a great project in exposing us to how to work with all the personnel who were involved within the unit.”

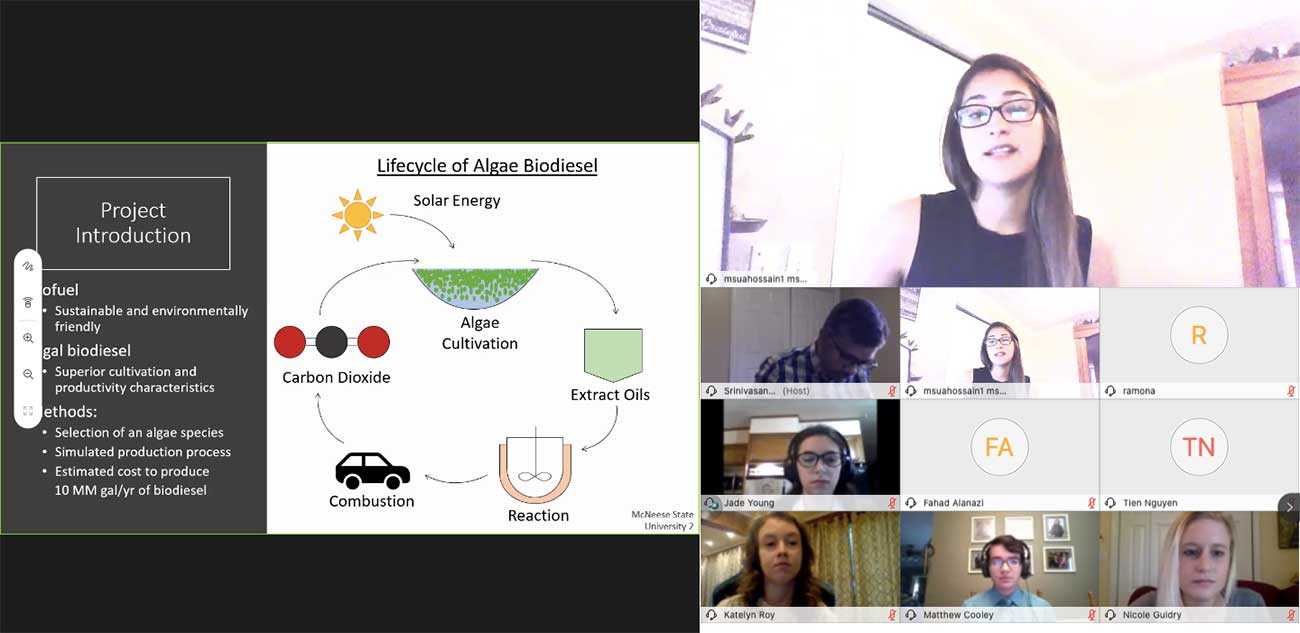

At the end of the semester, students put together 30-minute Zoom lectures that they presented live for faculty, mentors and other students. Presenters walked the audience through their processes, discoveries and innovations, detailing unexpected challenges they faced and their ultimate solutions.

Simbarashe Mambiri, whose team worked on the project “Improvements in Process Efficiencies to Produce POMMs From Stranded Natural Gas” for Michigan-based company GasTechno, says, “We have now learned how to develop a process from the conceptual stage and build it into an actual business line. We’re coming out of McNeese with a degree and with the bench skills that prepare us to work in industry.”

CEO of GasTechno and mentor Walter Breidenstein says that the work done by his student team far exceeded his expectations.

“What I asked students to do was take the existing process and improve it, but I didn’t expect them to take and build a whole new system. But as they started the project, the team members came back and said, ‘Listen, we redesigned this entire process to double production by adding more equipment to the process.’ And that was something I never thought about. So the students looked beyond what I had asked and actually redesigned and rebuilt the entire process. I was very excited about their work and I’m very happy with the results.”

Dr. Srinivasan Ambatipati, assistant professor of engineering, says that these senior capstone projects play a key role in training and preparing students for their careers.

“Part of this exercise involves improving their team building, problem solving, project management and communications skills. These skills, along with the engineering knowledge they have gained during their education at McNeese, make them the ideal candidates for recruitment by local industry. I am extremely satisfied with the students output backed up by positive feedback from the mentors on the quality of student presentations.”

Want more stories like this one sent straight to your inbox every week? Sign up for our McNeese eNewsletter!

The Office of Marketing and Communications

4205 Ryan Street

Lake Charles, LA 70609

337-475-5640

communications@mcneese.edu