Industry Training

The Institute for Industry – Education Collaboration (IIEC) at McNeese State University has training equipment that you can use with your own trainers to train your own new hires or incumbent operators.

Model Chemical Plant

The Institute for Industry-Education Collaboration offers a Model Chemical Plant that can be used to train new operators in the various types of equipment typically used in a chemical plant. This includes distillation units, a 25-foot confined space training vessel, and a control room.

The Hands On Trainer (HOT) Unit

The HOT Unit Trainer is designed for operators to practice troubleshooting on industrial process unit equipment and controls while they gain more understanding about the operations. Its design allows operators to take industrial components in and out of service, troubleshoot existing unit problems and give them an understanding of levels, temperature and flow control schemes. The design of the system includes a variety of valves and piping connections common in the chemical and petrochemical industry; thus enhancing the operator’s knowledge to identify and understand their application. The HOT Unit Trainer gives operators a multitude of exercises and procedures that will broaden their skill level, to become better employees as part of the industrial work force.

The following are some brief descriptions of the Hands On Trainer equipment and capabilities associated with the training of future Petrol-Chemical operators and Engineers.

- The unit has two sets of controls: a temperature control scheme for the water heater (H-101) and a level control scheme for the product tank (TK-102).

- The sight glass components for the tanks are large and durable; feed tank (TK-101) is equipped with an armored gauge column sight glass and the product tank (TK-102) with a magnetic column sight glass.

- Vents and drains are installed on each side of the heat exchanger so that it can be taken out of service along with additional piping on the tube side to provide back flushing capability for exercises.

- There are two duplex strainers placed in parallel to show the difference between a clean and fouled strain. Each strainer has the capability of being vented and drained.

- The unit incorporates as many different types of valves as possible; gate valves, globe valves, ball valves, check valves, safety ball check valves and a relief valve.

- The unit can be skid-mounted; the area of the completed system is no larger than 12’x 25’.

- All piping supports and piping are welded and flanged connected.

The HOT unit is controlled by an Emerson Delta V system and a Honeywell TDC 3000 system.

A manual with 120 procedures that you can follow on the HOT unit as well as P&ID diagrams can be made available for review upon request.

The Glycol Unit

The Glycol Unit is a continuous vacuum distillation unit that will separate a binary mixture of glycol and water (50/50 wt%). This process unit will put into practice fundamentals of distillation to produce 99%+ purity water and glycol products. The Glycol Unit is designed work in conjunction with the existing HOT Unit. The tanks, pumps, heater, exchanger, and control valves on the HOT Unit are integral to the performance of the Glycol Unit.

The Glycol Unit is designed using industrial engineering standards ensuring that the components installed are of the same make and from the very same manufacturers the student will encounter in industry. In addition, its components are configured and installed as they are in industry. The Glycol unit can be used to demonstrate key components of distillation including binary distillation, pressure manipulation through vacuum, wide ranges of feed composition mixtures, temperatures, and reflux ratios.

The Glycol Unit will be controlled from existing Emerson Delta V and Honeywell systems, same as the HOT Unit.

The Confined Space Training Vessel

The confined space training vessel is 5 feet in diameter and it contains 4 real life distillation trays about 3 feet apart. There is a manhole about 10 feet from the ground through which trainees can enter the vessel. The trainees can then move down through a couple of trays before finally exiting the vessel through the egress door at the bottom. In addition to confined space training, the vessel can be used for PPE and ladder training.

Training Room

The training room is located in ETL 111. It is exclusively used for professional development and training activities. It is located a few yards away from the HOT, Glycol Distillation, Confined Space Training Units and the control room and computer simulation classroom. It is equipped with an overhead projector, Apple TV for wireless streaming to the projector, an audio system with wireless handheld and lapel type microphones, whiteboards, easels, 40 chairs that roll and swivel, and a number of folding tables of various lengths that can be arranged depending on the type of activity scheduled in the room.

The training room has plenty of space to bring in cutaways and other movable equipment to be used during training.

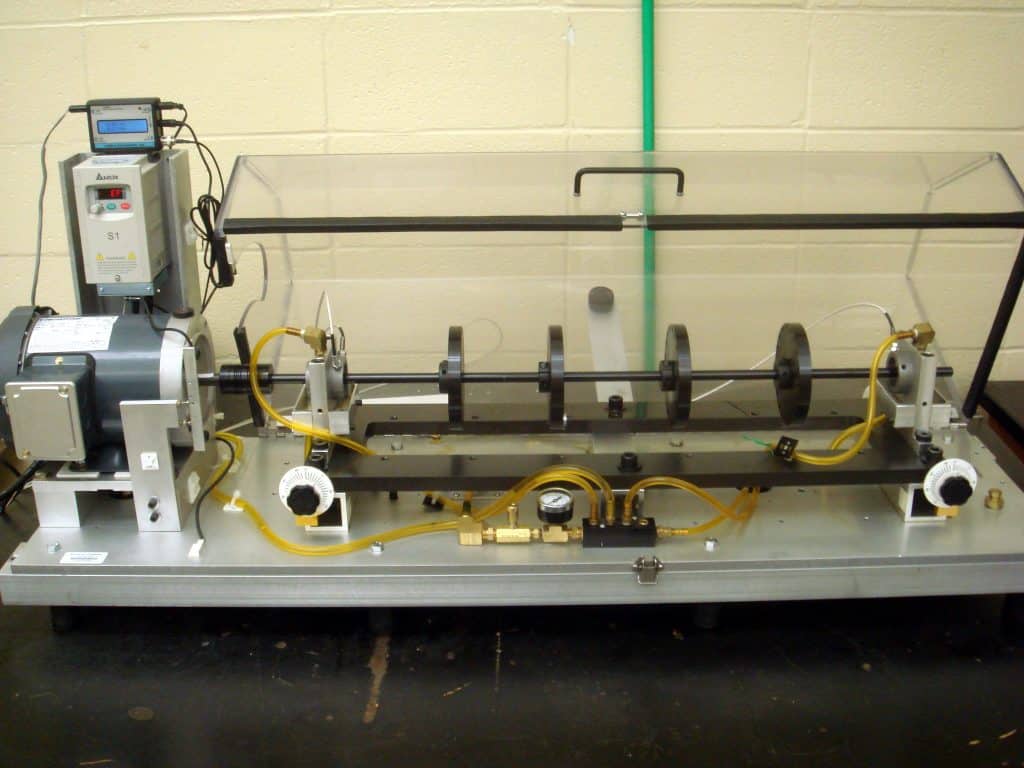

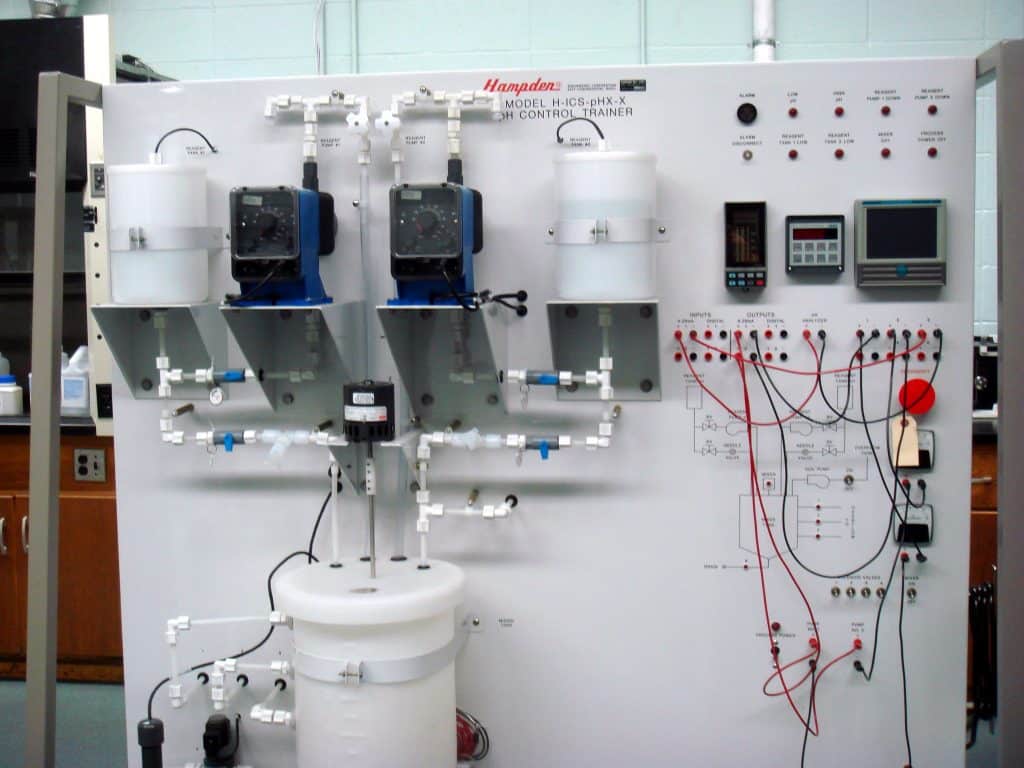

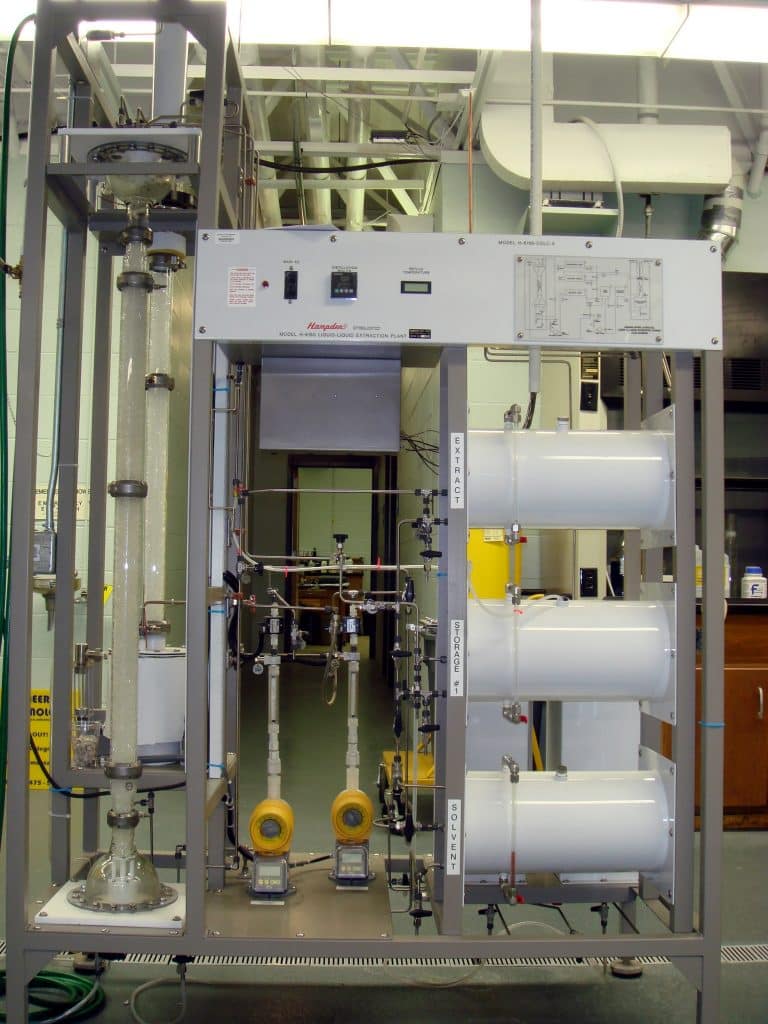

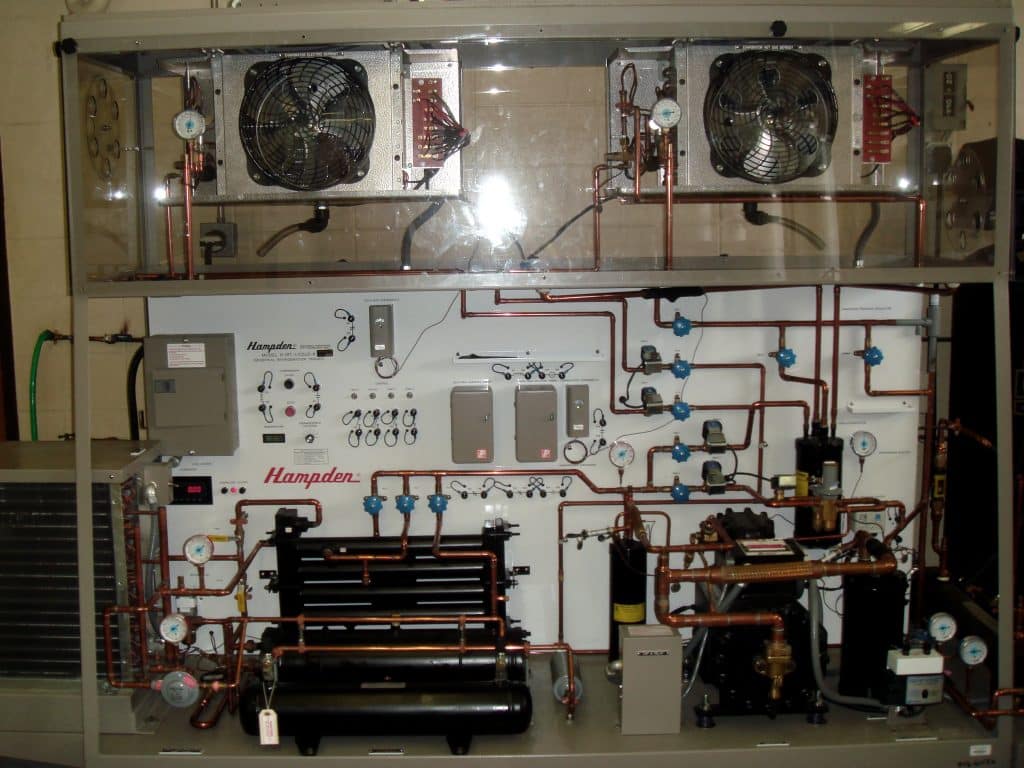

Laboratory Equipment

The IIEC has a plethora of additional resources that could be used by your trainers as part of their training curriculum. The pictures below are only a small part of our inventory of equipment and cutaways.

Please feel free to contact us for a personal tour of our facilities so you can see everything we have to offer as part of your training curriculum.